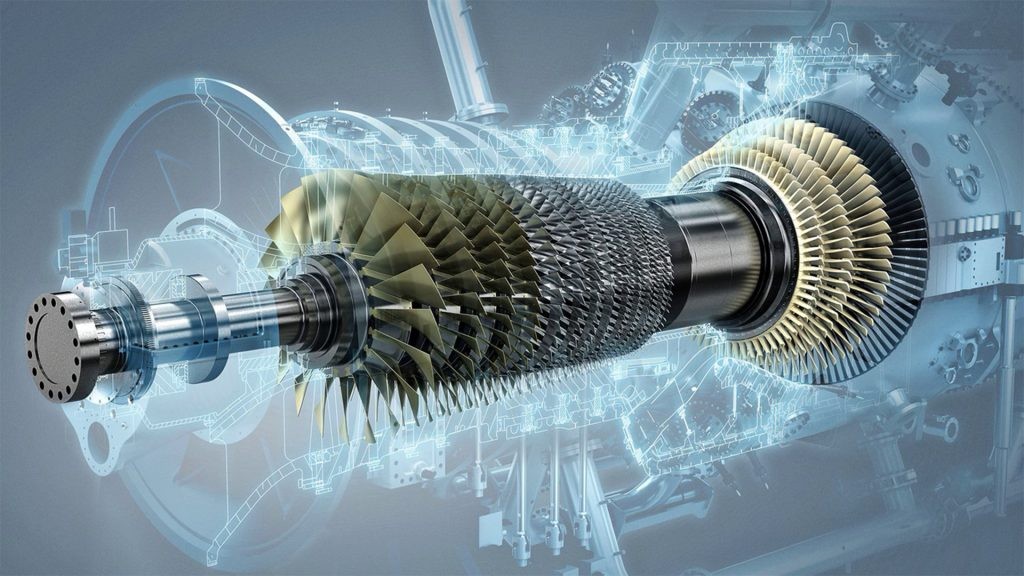

Steam Turbines Valves Reliability & Integrity Training Course

API 598, Valve diagnostic, Inspection, Testing and Troubleshooting TTV, Governor/Control and Non-Return Valves (NRV)

Session Details

USD 4,500.00

Overview

Steam turbine valves are typically so reliable they are often overlooked. However, the inspection and maintenance of these valves is critical. In today’s increasingly competitive energy market, major turbine inspection intervals have been extended. In some cases, maintenance planners or plant operators also extend turbine valve inspection and maintenance to coincide with turbine major inspections. This has often resulted in valve failures and steam turbine over speed events, some of which have been catastrophic. Risk exposures associated with untimely or improper steam turbine valve maintenance include:

Downstream steam path damage due to debris and solid particle erosion

Oil leaks resulting in fire under valve areas

Complete destruction of the unit from over speed, including likely fire and hydrogen explosion resulting from over speed energy release

Failure to perform timely inspections and maintenance can lead to the total destruction of a steam turbine generator as a result of a valve not functioning and closing as required. This course is designed to provide participant with a detailed and up-to-date overview of STEAM TURBINE VALVES inspection and testing in accordance with API 598. It covers the API requirements needed to perform inspection, examination, supplementary examinations and pressure testing requirements for resilient-seated, non-metallic-seated and metal-to-metal-seated valves of the gate, globe, plug, ball, check and butterfly types.

During this course, participants will learn to inspect, examine and perform supplementary examination; carryout pressure testing, Identify test location, test equipment and test required; differentiate high-pressure closure test and high-pressure pneumatic test; identify test fluid; test pressures, test duration and test leakage; employ pressure testing procedures including backseat testing, shell testing, low-pressure and high-pressure closure testing, double block and bleed high-pressure closure testing; and explain in details the valve certification and retesting.

Course Objectives

Upon completion of this course, the participants shall be able to:

Apply and gain an-depth knowledge on valve inspection and testing in accordance with the international standard API 598

Inspect, examine and perform supplementary examination covering inspection of valve manufacturer’s plant, inspection notice and extent of inspection

Carryout pressure testing as well as identify test location, test equipment and tests required

Differentiate high-pressure closure test and high-pressure pneumatic test

Describe test fluid, test pressures, test duration and test leakage

Employ pressure testing procedures including backseat testing, shell testing, low-pressure and high-pressure closure testing, double block and bleed high-pressure closure testing

Explain in details the valve certification and retesting comprising of certificate of compliance and retesting

Who Should Attend

This course provides a wide understanding and a deeper appreciation for an overview of all significant aspects and considerations of steam valve maintenance, inspection, and testing in accordance with the international standard API 598 for process, piping, pipelines, and pressure vessels engineers and supervisors who inspect and install pressure relief devices, and engineers involved in plant turnaround and upgrade projects.. Further, it is suitable for:

Maintenance & Reliability Engineers / Supervisors / Team Leaders

Inspection and QA & QC Engineers / Supervisors / Team Leaders

Steam generation and process plant equipment specialists, maintenance staff.

Course Methodology

The BK Management Team believes that learning is not only about acquiring technical skills, it is also about learning behaviors & Competencies that are desirable for work in plant operation & maintenance, critical dimensions. Our holistic teaching develops our delegates' personal effectiveness to function both as individuals and as team players.

The course delivery & modes of instruction will incorporate Hands-on Practical Sessions using equipment, State-of-the-Art Simulators (as required), Drawings, Case Studies, Videos, Exercises, Theory, Practical skills, and Q&A sessions.

To enhance learning outcomes, theory sessions will comprise classroom-based lectures that will be interspersed with interactive discussions, scenario-based, case-study, group exercises, video clips, PowerPoint slides, learners' Guide, and the application of various tools, which will be provided to help the delegates and participants of the learning objectives. With the successful implementation of the learnt skills, they are bound to enhance Individual & Organizational growth.

For online / Interactive Virtual sessions, the Delegate should have a stable & good Internet connection on their Laptop.

Course Outline

Introduction

Steam Turbine Arrangements and Applications

Type of Steam

Exhaust System Configuration

Grouping and Number of Turbine Stages

Turbine Arrangements

Single Stage Small Steam Turbines

Multistage Medium Size Steam Turbines

Single Casing Admission/Extraction Multistage Steam Turbines

Turbine Component Characteristics and Failure Mechanisms

Steam Turbine valves, types, function and Applications

API 598 overview

Steam Turbine Valve Risk Exposure and safety requirements

Stop, Trip & Throttle, and Intercept Valves

Inspection, Examination & Supplementary Examination

Inspection ASPECTS AND Notice

Extent of Inspection

Examination

Supplementary Examination

Pressure Tests and Test arrangement

Test requirements

Test Equipment and instruments

High Pressure Closure Test

High Pressure Pneumatic Shell Test

Test Fluid and standard pressure

Test Duration

Test Leakage

Pressure Test Procedures

Backseat Test

Shell Test

Low-Pressure Closure Test

High-Pressure Closure Test

Double Block & Bleed High-Pressure Closure Test

Certification of Compliance

Governor/Control Valves

Inspection, Examination & Supplementary Examination

Inspection ASPECTS AND Notice

Extent of Inspection

Examination

Supplementary Examination

Pressure Tests and Test arrangement

Test requirements

Test Equipment and instruments

High Pressure Closure Test

High Pressure Pneumatic Shell Test

Test Fluid and standard pressure

Test Duration

Test Leakage

Pressure Test Procedures

Backseat Test

Shell Test

Low-Pressure Closure Test

High-Pressure Closure Test

Double Block & Bleed High-Pressure Closure Test

Certification of Compliance

Steam Turbine Inlet Control Valve

Safety Requirements

Present Valve Design

Sealing

Valve Forces

Admission, Extraction, and Non-Return Valves (NRV)

Inspection, Examination & Supplementary Examination

Inspection ASPECTS AND Notice

Extent of Inspection

Examination

Supplementary Examination

Pressure Tests and Test arrangement

Test requirements

Test Equipment and instruments

High Pressure Closure Test

High Pressure Pneumatic Shell Test

Test Fluid and standard pressure

Test Duration

Test Leakage

Pressure Test Procedures

Backseat Test

Shell Test

Low-Pressure Closure Test

High-Pressure Closure Test

Double Block & Bleed High-Pressure Closure Test

Certification of Compliance

Retesting

Failures due to untimely valve maintenance

Failure of the valve stems due to solid particle erosion

Failures of the main steam stop valve screen or strainer

Oxides build up on valve stems resulting in stem binding prior to full closure

Valve stems distorting and bending resulting in binding prior to closing

Operating hydraulic system debris and contamination build up

Operating hydraulic oil system leaks

Valve linkage wear and binding

Valve seat cracking and liberation

Session Details

USD 4,500.00

Do you have any questions ?

Jubail Industrial City, Saudi Arabia

373 road 112, First Industrial Area, Unit No.: 1 Al Jubail 35717 - 7043 KSA

Explore

About

© 2026 BK Consultancy & Training

All rights reserved.